Located in the scenic landscape of Oregon, this recreational area offers diverse outdoor activities and serves as a key destination for nature enthusiasts. Its geographical coordinates place it within easy reach of urban centers while providing a natural escape.

The area’s significance lies in its blend of recreational opportunities, ecological preservation, and historical context. It supports a range of activities, from camping and picnicking to river access and trail exploration, all while contributing to the conservation of local flora and fauna. The site has played a role in the region’s development, serving as a gathering place for generations.

Further discussion will delve into the specific amenities, recreational options, and environmental considerations that define this valuable outdoor space. This analysis will present details on accessibility, usage patterns, and ongoing efforts to maintain its ecological integrity.

Effective utilization of the recreational area requires informed planning and adherence to established guidelines. The following recommendations are designed to enhance the experience and ensure responsible stewardship of the environment.

Tip 1: Secure Reservations in Advance: Due to high demand, particularly during peak seasons, securing reservations for camping sites or designated picnic areas is strongly advised. This proactive measure prevents potential disappointment and ensures access to desired facilities.

Tip 2: Adhere to Posted Regulations: Familiarization with and strict adherence to posted regulations regarding noise levels, pet control, and trail usage is imperative. Compliance minimizes disruption to other visitors and safeguards the natural environment.

Tip 3: Practice Leave No Trace Principles: Visitors bear the responsibility of minimizing their impact on the environment. Packing out all trash, staying on designated trails, and avoiding disturbance to wildlife are fundamental components of responsible recreation.

Tip 4: Prepare for Variable Weather Conditions: Oregon’s weather can be unpredictable. Checking the forecast and packing appropriate clothing, including rain gear and layers, is crucial for maintaining comfort and safety.

Tip 5: Exercise Caution Near Waterways: Rivers and creeks present inherent risks. Maintaining constant supervision of children, avoiding swimming in unauthorized areas, and being aware of swift currents are essential safety precautions.

Tip 6: Be Mindful of Wildlife: The area is home to diverse wildlife. Maintaining a safe distance from animals, avoiding feeding them, and properly storing food are critical for both visitor safety and wildlife preservation.

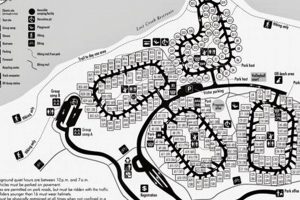

Tip 7: Utilize Available Resources: Park maps, information kiosks, and ranger stations provide valuable resources for navigating the area, understanding its history, and reporting any concerns or incidents.

By adhering to these guidelines, visitors can contribute to the preservation of this valuable resource while maximizing their enjoyment of its natural beauty and recreational opportunities. Proper preparation and responsible conduct are essential for ensuring a positive and sustainable experience.

The subsequent sections will further elaborate on specific aspects of the park’s ecology, recreational offerings, and ongoing management initiatives.

1. Camping Facilities

Camping facilities are an integral component, offering immersive experiences within the natural environment. Their presence allows visitors extended engagement, fostering a deeper connection with the parks resources. The availability and quality of these sites directly impact the parks appeal and utilization rates. For example, increased availability of well-maintained, reservable campsites correlates with higher visitor numbers and extended stays. This highlights the economic impact through tourism and recreation revenue.

The design and management of camping facilities within reflect environmental responsibility. Implementing sustainable practices such as designated fire pits, waste management protocols, and minimizing vegetation disturbance are crucial. Successful integration of infrastructure ensures recreational enjoyment and conserves the ecological integrity. The popularity requires careful balancing of visitor access with the preservation of natural resources, influencing decisions on campsite density and permissible activities.

The effectiveness of camping facilities in contributes to the area’s overall success. Ensuring equitable access, maintaining cleanliness, and providing adequate safety measures are ongoing challenges. Addressing these proactively strengthens the park’s reputation as a premier outdoor destination, ultimately promoting environmental stewardship and supporting the local community.

2. Riverside Access

Riverside access constitutes a foundational element of the recreational areas appeal and functionality. The area’s geographical setting, adjacent to the Clackamas River, directly enables a spectrum of water-based activities, including fishing, swimming, and boating. These activities are primary drivers for visitation, influencing recreational user patterns and overall economic impact. Restricting or enhancing river accessibility correspondingly affects the area’s attractiveness and utility.

The physical infrastructure supporting riverside access, such as boat ramps, designated swimming areas, and riverbank stabilization measures, is crucial for ensuring both user safety and environmental protection. Properly maintained boat ramps facilitate controlled river entry and exit, minimizing bank erosion. Designated swimming areas, demarcated and monitored for safety, channel recreational activity away from sensitive habitats. Effective riverbank stabilization projects mitigate erosion, preserving water quality and protecting riparian ecosystems. These features are examples of how direct access requires careful planning and execution to prevent ecological degradation.

In conclusion, riverside access is not merely an amenity but a defining characteristic that shapes the area’s identity and purpose. Balancing recreational demands with ecological sustainability is an ongoing challenge, requiring adaptive management strategies, community engagement, and continuous investment in infrastructure and conservation initiatives. Future success hinges on prioritizing responsible access that safeguards the long-term health of the river ecosystem and continues to provide recreational opportunities for generations to come.

3. Hiking Trails

Hiking trails are an essential component, fundamentally shaping its recreational identity. Their presence facilitates immersive engagement with the natural environment, offering opportunities for physical activity, nature appreciation, and solitude. The condition and diversity of these trails directly affect visitor experiences and, consequently, visitation rates. For example, a well-maintained trail network, catering to various skill levels, attracts a broader demographic, enhancing the park’s overall appeal and utilization. Conversely, neglected or poorly marked trails detract from the visitor experience and increase the risk of accidents.

The design and maintenance of hiking trails within involve careful consideration of environmental factors. Sustainable trail construction techniques, such as minimizing vegetation disturbance and implementing erosion control measures, are crucial for preserving the integrity of the surrounding ecosystems. Strategic trail placement can guide visitors away from sensitive habitats, protecting vulnerable flora and fauna. The implementation of signage, providing information about trail difficulty, length, and points of interest, enhances visitor safety and promotes responsible trail use. For instance, trails adjacent to the Clackamas River may necessitate specific safety precautions, such as fencing or warning signs, to prevent accidental falls or access to dangerous areas.

The effectiveness of the trail system directly influences the area’s success as a recreational destination. Regular maintenance, addressing issues such as erosion, fallen trees, and vandalism, is imperative for ensuring visitor safety and preserving trail quality. Incorporating interpretive elements, such as informational kiosks or guided nature walks, can enhance the educational value of the trails, fostering environmental awareness and stewardship. Therefore, strategic investment in trail infrastructure and management is critical for sustaining the park’s ecological health and enhancing its recreational value for future generations.

4. Picnic areas

Picnic areas are a fundamental amenity, strategically integrated within the recreational area’s landscape to enhance visitor experience and facilitate social interaction with the natural environment. Their design, location, and maintenance directly influence visitor satisfaction and the area’s overall appeal.

- Designated Locations and Accessibility

Designated picnic sites are positioned throughout the area, often near scenic overlooks, river access points, or trailheads, optimizing convenience and enhancing the recreational experience. Accessibility is prioritized, with many sites offering parking proximity and accommodating various mobility levels. Strategic placement minimizes environmental impact by concentrating activity in designated zones, reducing the potential for widespread disturbance.

- Infrastructure and Amenities

These sites commonly feature picnic tables, fire rings or grills, and refuse receptacles. The presence and quality of these amenities directly impact visitor satisfaction. Regular maintenance, including cleaning and repair, is essential for preserving the sites’ functionality and attractiveness. Additionally, the availability of shade structures or natural shade from trees enhances comfort, especially during peak seasons.

- Social and Recreational Function

Picnic areas serve as central gathering places for families and groups, fostering social interaction and providing opportunities for shared recreational experiences. These sites facilitate activities such as outdoor dining, games, and relaxation, enriching the overall visitor experience. Well-maintained and strategically located picnic areas contribute to a sense of community and promote responsible park stewardship.

- Environmental Considerations

The management of picnic areas involves careful consideration of environmental impacts. Implementing effective waste management strategies, such as providing ample refuse receptacles and promoting “leave no trace” principles, is crucial for preventing litter and protecting natural resources. Additionally, designated fire rings or grills help contain fires and minimize the risk of wildfires. Regular monitoring and maintenance ensure these sites are managed sustainably.

These facets collectively underscore the importance of picnic areas within the recreational area. Their strategic integration, coupled with responsible management practices, contributes to a high-quality visitor experience while minimizing environmental impact. Continuing to prioritize accessibility, infrastructure, and environmental stewardship is essential for ensuring these amenities remain a valuable resource for all visitors.

5. Natural environment

The natural environment forms the bedrock upon which the recreational area is built. This geographical space is inherently defined by its ecological components, including the Clackamas River, riparian zones, forested areas, and diverse wildlife populations. These elements are not merely aesthetic assets; they constitute the very essence of the visitor experience, driving recreational activities and influencing the area’s overall character. The condition of this surrounding landscape directly impacts water quality, air purity, and the viability of diverse habitats, subsequently determining the sustainability and long-term utility of the space. Degradation of the natural environment, stemming from pollution, erosion, or invasive species, directly undermines the area’s recreational value and ecological integrity. For example, increased sedimentation in the Clackamas River due to upstream logging activities negatively affects fish populations and water clarity, diminishing the appeal for fishing and swimming activities.

Effective management and conservation efforts are crucial to mitigate these threats and preserve the ecological health of the recreational area. Restoration initiatives, such as riparian planting projects and invasive species removal programs, aim to enhance habitat quality and promote biodiversity. Sustainable trail development and responsible recreation practices are essential for minimizing human impact on sensitive ecosystems. Regulatory frameworks, enforced through park rangers and public awareness campaigns, play a pivotal role in preventing environmental damage and promoting responsible stewardship. Furthermore, monitoring programs, assessing water quality, air purity, and wildlife populations, provide essential data for informing management decisions and evaluating the effectiveness of conservation strategies. These conservation steps guarantee the sustainable future of the resource.

The intimate connection between the natural environment and the recreational area demands a holistic and adaptive management approach. Recognizing the interdependence of ecological health and recreational value is fundamental to ensuring long-term sustainability. Challenges persist, including balancing recreational demands with environmental protection, addressing the impacts of climate change, and securing adequate funding for conservation initiatives. Successfully navigating these challenges requires collaboration among government agencies, community organizations, and individual visitors, fostering a shared commitment to preserving this valuable natural asset for future generations. The integration of ecological sustainability into all facets of area management constitutes a practical investment in its long-term viability and the well-being of the surrounding community.

6. Wildlife Viewing

The opportunity for wildlife viewing significantly enhances the recreational experience within the defined area. The park’s diverse ecosystems, including riparian corridors, forested uplands, and aquatic habitats, support a variety of animal species, rendering it an attractive location for enthusiasts and researchers alike. Avian species, such as bald eagles, ospreys, and various songbirds, are commonly observed along the Clackamas River. Terrestrial fauna, including deer, coyotes, and smaller mammals, inhabit the forested regions. The presence and accessibility of these species directly influence the park’s appeal as a nature-based tourism destination. For instance, sightings of bald eagles contribute to increased visitor interest and provide educational opportunities for both residents and tourists. The inherent value of such viewing drives the need for active conservation.

Conservation efforts within are intrinsically linked to maintaining and enhancing wildlife viewing opportunities. Habitat preservation, including the protection of riparian zones and reforestation initiatives, is crucial for sustaining diverse wildlife populations. Management strategies that minimize human disturbance, such as designated viewing areas and restrictions on off-trail activities, further contribute to wildlife protection. Educational programs and interpretive signage play a role in raising awareness among visitors about responsible wildlife viewing practices and the importance of respecting natural habitats. An example of this is the establishment of designated bird-watching areas along established trails that aim to lessen disruption to breeding zones while providing vantage points for observers.

In conclusion, wildlife viewing stands as a key component of the experience within the defined boundaries. Effective management requires a balanced approach that prioritizes both visitor access and wildlife conservation. Ongoing monitoring of wildlife populations and habitat conditions, coupled with adaptive management strategies, is essential for ensuring the long-term sustainability of viewing opportunities. The successful integration of conservation efforts and visitor engagement will ultimately determine the capacity to protect the biodiversity and preserve its recreational value for future generations. This integration is a testament to the careful and proactive management of natural resources within Oregon.

7. Location advantages

The geographic placement of the recreational area offers distinct advantages that contribute significantly to its recreational appeal and regional importance. Its accessibility, environmental characteristics, and proximity to urban centers synergistically enhance its value to both visitors and the surrounding communities.

- Proximity to Urban Centers

The area’s relative proximity to Portland and other metropolitan areas facilitates easy access for day trips and weekend excursions. This accessibility significantly broadens its user base, attracting a diverse range of visitors seeking outdoor recreation without extensive travel. Consequently, the area serves as an accessible natural retreat for urban dwellers, providing respite from city life. This proximity directly influences visitation rates and contributes to local tourism revenue.

- Access to Natural Resources

Located along the Clackamas River, the area benefits from direct access to diverse aquatic resources, including fishing, swimming, and boating opportunities. The presence of the river, coupled with surrounding forested areas, creates a diverse ecosystem that supports a wide range of wildlife. This natural endowment enhances the area’s appeal as a nature-based recreation destination, attracting visitors interested in outdoor pursuits and nature appreciation. It is a significant attribute that shapes recreational activities and promotes environmental stewardship.

- Transportation Infrastructure

The presence of well-maintained roadways and transportation infrastructure facilitates convenient access to the recreational area for visitors arriving from various locations. This accessibility is crucial for maximizing visitation and ensuring a positive visitor experience. Well-marked routes and ample parking facilities enhance ease of access, encouraging visitors to explore and utilize its amenities. Effective transportation planning is integral to the successful management and utilization of the area.

- Climate and Seasonal Variation

The climate of the region contributes to the viability of the recreational area as a year-round destination. Moderate temperatures during spring and fall, coupled with warm summers, support a range of outdoor activities. Seasonal variations in precipitation influence river levels and vegetation patterns, creating dynamic landscapes that attract visitors throughout the year. Recognizing and adapting to climatic factors are crucial for managing recreational activities and ensuring visitor safety.

These locational facets, acting in concert, underscore the significance of the recreational area as a regional asset. Its accessibility, natural resources, transportation infrastructure, and climate collectively contribute to its recreational appeal and economic value. Continued strategic planning and resource management are essential for sustaining these advantages and ensuring the area remains a valuable destination for future generations.

Frequently Asked Questions About Barton Park Oregon

The following questions address common inquiries regarding access, amenities, regulations, and environmental considerations related to the recreational area.

Question 1: Are reservations required for camping within the Oregon park?

Reservations are highly recommended, particularly during peak seasons (summer months and holidays), to guarantee campsite availability. Reservations can be made through the designated online reservation system or by contacting the park directly.

Question 2: What are the designated swimming areas within the Oregon park, and what safety precautions should be observed?

Designated swimming areas are typically marked with signage and buoys. It is essential to swim only in designated areas, supervise children closely, and be aware of river currents and potential hazards. Swimming is not permitted in areas with strong currents or restricted access.

Question 3: Are pets allowed within the Oregon park, and what regulations apply?

Pets are generally permitted within the park, but they must be kept on a leash at all times and under the owner’s control. Pet owners are responsible for cleaning up after their pets and disposing of waste properly. Certain areas may have restrictions on pet access, which will be clearly marked.

Question 4: What are the regulations regarding campfires within the Oregon park?

Campfires are permitted only in designated fire rings or grills. Visitors must adhere to fire safety regulations, including ensuring that fires are completely extinguished before leaving the campsite. Firewood may be available for purchase within the park, and gathering firewood from the surrounding forest is generally prohibited.

Question 5: What recreational activities are available within the Oregon park besides camping and swimming?

In addition to camping and swimming, the park offers opportunities for hiking, fishing, picnicking, wildlife viewing, and boating. A network of hiking trails caters to various skill levels, and the Clackamas River provides opportunities for fishing and boating activities. Picnic areas are strategically located throughout the park, offering scenic views and convenient access to amenities.

Question 6: What are the primary conservation efforts aimed at preserving the natural environment within the Oregon park?

Conservation efforts focus on habitat restoration, invasive species removal, and water quality protection. Riparian planting projects aim to restore riverbank vegetation, while invasive species removal programs target non-native plants that threaten native ecosystems. Water quality monitoring and management strategies are implemented to protect the Clackamas River from pollution and sedimentation.

Visitors should be aware of these regulations to ensure a safe and enjoyable experience while minimizing their impact on the park’s natural resources.

Further sections will address specific ecological considerations and ongoing management initiatives within the park.

Conclusion

This analysis has presented a comprehensive overview, detailing its multifaceted attributes and significance. From its recreational amenities, including camping and river access, to its critical ecological role and location advantages, the examination reveals an interwoven relationship between visitor experience and environmental sustainability.

Continued adherence to responsible management practices, adaptive planning in response to environmental changes, and collaborative engagement among stakeholders are essential. Ensuring its long-term viability necessitates a dedicated commitment to preserving its natural integrity while providing opportunities for recreation and education for current and future generations.