Facilities in this region provide a range of manufacturing services, typically including machining, fabrication, and repair work. These businesses cater to diverse needs, from prototyping and small-batch production to large-scale manufacturing. The geographic location influences the types of industries served and the specialized capabilities offered.

The presence of such establishments fosters economic growth through job creation and support for local industries. They contribute to innovation by enabling the development and production of new products and technologies. Historically, these shops have been vital to industries like timber, agriculture, and transportation, adapting over time to serve emerging sectors.

Subsequent sections will delve into the specific capabilities offered by these establishments, the industries they support, and factors to consider when selecting a provider within the region.

Selecting a machining service provider requires careful evaluation to ensure project success. Factors ranging from technical capabilities to logistical considerations influence the outcome.

Tip 1: Assess Project Requirements: Clearly define the project scope, material specifications, tolerances, and quantities before seeking quotes. A detailed specification facilitates accurate cost estimation and reduces the potential for misunderstandings.

Tip 2: Evaluate Machining Capabilities: Verify that the provider possesses the necessary equipment and expertise to handle the project’s technical demands. Consider the types of CNC machines, their capacity, and the provider’s experience with similar projects and materials.

Tip 3: Review Quality Control Procedures: Inquire about the provider’s quality assurance processes, including inspection methods, metrology equipment, and adherence to industry standards. Request examples of quality control documentation or reports.

Tip 4: Consider Lead Times and Delivery Schedules: Discuss realistic lead times and delivery schedules, taking into account the complexity of the project and the provider’s current workload. A clearly defined timeline is crucial for project planning.

Tip 5: Investigate Material Sourcing: Understand the provider’s material sourcing practices. Determine if they can procure the specified materials or if the client must supply them. Verify material certifications and traceability.

Tip 6: Clarify Communication Protocols: Establish clear communication channels and protocols for project updates, issue resolution, and feedback. Regular communication ensures alignment and minimizes delays.

Tip 7: Evaluate Proximity and Logistics: Proximity to the client’s location can affect shipping costs and lead times. Consider the provider’s logistics capabilities and accessibility.

These considerations contribute to a well-informed decision, leading to successful machining projects and efficient manufacturing processes.

The subsequent section provides a concluding summary of the key factors discussed.

1. Precision Machining Capabilities

Precision machining capabilities are a foundational element of competent machine shops operating in the Eugene, Oregon area. The availability of advanced equipment and skilled machinists directly influences the range and complexity of projects that can be undertaken. The ability to consistently achieve tight tolerances, often measured in thousandths of an inch or even microns, is critical for producing high-quality parts that meet demanding specifications. For instance, the fabrication of components for scientific instruments or medical devices requires exceptional precision to ensure proper function and reliability. Absence of such capabilities limits the scope of work and potential client base.

The connection is causal: investment in precision machining equipment (e.g., CNC milling machines, lathes with live tooling, coordinate measuring machines) and ongoing training for machinists directly results in an enhanced ability to manufacture intricate parts with close tolerances. This, in turn, allows machine shops to serve industries such as aerospace, defense, and semiconductor manufacturing, which demand high levels of accuracy. A real-world example might involve a local machine shop securing a contract to produce custom optics housings. The success of this project hinges on the shop’s ability to hold extremely tight dimensional tolerances and surface finishes, a direct result of its investment in precision machining capabilities.

In summary, precision machining capabilities are not merely an option, but a necessity for machine shops seeking to thrive in the competitive manufacturing landscape of Eugene, Oregon. They enable these businesses to attract higher-value projects, serve a broader range of industries, and ultimately contribute to the economic vitality of the region. Overcoming the challenges of acquiring and maintaining state-of-the-art equipment and attracting skilled machinists is essential for long-term success.

2. Material Expertise

Material expertise constitutes a critical determinant of a machine shop’s success, particularly within the diverse manufacturing environment of Eugene, Oregon. The proficiency of a machine shop in understanding and working with a range of materials directly affects the quality, durability, and performance of the finished product. This expertise goes beyond simply knowing how to cut a specific material; it involves understanding its properties, behavior under different conditions, and the optimal machining techniques for achieving desired results.

- Material Selection and Suitability

The ability to select the most appropriate material for a given application is paramount. This includes considering factors such as strength, weight, corrosion resistance, and cost. For example, if a machine shop is contracted to produce components for outdoor equipment, they must possess the knowledge to select materials resistant to weathering and UV exposure. Inappropriate material selection leads to premature failure and increased costs.

- Machining Parameter Optimization

Different materials require distinct machining parameters, including cutting speeds, feed rates, and coolant types. A machine shop with strong material expertise understands how to optimize these parameters to prevent issues such as work hardening, tool wear, and surface defects. For instance, machining titanium alloys requires significantly different techniques than machining aluminum, owing to titanium’s higher strength and lower thermal conductivity. Improper parameter selection results in increased scrap rates and reduced efficiency.

- Welding and Fabrication Considerations

For machine shops that offer welding and fabrication services, material expertise extends to understanding the compatibility of different materials and the appropriate welding techniques to ensure strong, durable joints. The incorrect choice of welding filler metal or improper welding procedure results in weak welds prone to cracking or corrosion. Consider the fabrication of a stainless steel food processing vessel; selecting the correct grade of stainless steel and employing appropriate welding techniques are crucial for maintaining hygiene and preventing contamination.

- Material Sourcing and Traceability

Understanding material sourcing and ensuring traceability is increasingly important, particularly in regulated industries such as aerospace and medical devices. A machine shop with material expertise establishes relationships with reputable suppliers and implements systems to track the origin and properties of the materials they use. This ensures compliance with industry standards and allows for rapid identification and resolution of any material-related issues. Lack of material traceability can result in significant legal and financial repercussions.

These considerations illustrate that material expertise is not merely a desirable attribute but an essential competency for machine shops in the Eugene, Oregon area. It impacts all aspects of the manufacturing process, from material selection to quality control, and ultimately determines the success and reputation of the business. Ignoring or underestimating the importance of material expertise can lead to costly errors, dissatisfied clients, and a diminished competitive advantage.

3. Prototyping Services

Prototyping services offered by machine shops in Eugene, Oregon, represent a crucial link in the product development lifecycle, enabling the transformation of conceptual designs into tangible representations. These services allow engineers and designers to evaluate functionality, identify potential design flaws, and refine product specifications before committing to full-scale production.

- Rapid Prototyping Techniques

Local machine shops employ various rapid prototyping techniques, including CNC machining, 3D printing, and laser cutting, to create prototypes with varying levels of complexity and precision. CNC machining offers advantages in terms of material selection and dimensional accuracy, while 3D printing enables the creation of complex geometries and intricate internal features. The choice of prototyping technique depends on factors such as the material requirements, design complexity, and budget constraints of the project. For instance, a machine shop might use CNC machining to create a functional prototype of a metal bracket, while 3D printing is employed to produce a plastic enclosure with intricate details.

- Design Refinement and Validation

Prototyping services provide a platform for design refinement and validation, allowing engineers and designers to test and evaluate the performance of their designs under real-world conditions. By creating physical prototypes, potential design flaws and limitations can be identified and addressed before committing to mass production. This iterative process helps to optimize product functionality, improve reliability, and reduce the risk of costly design errors. In the context of a machine shop in Eugene, Oregon, this process might involve creating multiple iterations of a prototype part for a local manufacturer, each time refining the design based on feedback from testing.

- Material Selection Optimization

Prototyping services enable the evaluation of different materials for a specific application. Machine shops can produce prototypes using various materials, allowing engineers to assess their suitability in terms of strength, weight, corrosion resistance, and cost. This process helps to optimize material selection and ensure that the final product meets the required performance characteristics. A local machine shop, for example, might create prototypes of a housing component using both aluminum and a composite material to determine which offers the best balance of weight and durability.

- Cost Estimation and Manufacturing Process Optimization

Creating prototypes provides valuable insights into the manufacturing process and allows for accurate cost estimation. Machine shops can use the prototyping process to identify potential manufacturing challenges, optimize tooling strategies, and estimate the time and resources required for mass production. This information is crucial for developing accurate cost estimates and ensuring that the product can be manufactured efficiently and cost-effectively. The machine shop in Eugene, Oregon, can utilize the prototyping phase to determine the optimal machining parameters and tooling required for producing a complex component in large quantities, providing a more accurate cost projection to the client.

The prototyping services provided by machine shops in Eugene, Oregon, are integral to fostering innovation and supporting the growth of local industries. By enabling rapid design iteration, material selection optimization, and manufacturing process refinement, these services contribute to the development of high-quality, cost-effective products that meet the evolving needs of the market.

4. CNC Machining Capacity

CNC machining capacity represents a critical element in evaluating the capabilities of any machine shop in Eugene, Oregon. This factor encompasses the number of CNC machines available, their size and configuration, and the skill of the machinists operating them. Adequate CNC machining capacity enables a machine shop to handle a diverse range of projects, from small-batch prototypes to large-scale production runs. The absence of sufficient capacity can lead to project delays, increased costs, and limitations on the types of parts that can be manufactured. For instance, a local manufacturer requiring a large quantity of precision-machined components will seek a machine shop with sufficient CNC machining capacity to meet their production schedule. If the shop lacks the necessary equipment or personnel, the manufacturer risks delays and potential disruptions to their own operations. The presence of robust CNC machining capabilities directly influences the competitive advantage of a machine shop.

The relationship is interdependent. Investment in CNC machining technology necessitates investment in skilled personnel capable of programming, operating, and maintaining the equipment. Conversely, a skilled workforce requires access to modern CNC machines to fully utilize their expertise. For example, a machine shop equipped with advanced 5-axis CNC milling machines can produce highly complex parts with greater efficiency and accuracy, provided they have machinists proficient in programming and operating these machines. Another practical application involves a machine shop securing a contract to produce parts for a local aerospace company. The success of this project hinges on the shop’s ability to meet stringent quality standards and tight deadlines, which in turn depends on their CNC machining capacity and the expertise of their machinists.

In summary, CNC machining capacity is not merely a quantitative metric but a qualitative indicator of a machine shop’s ability to deliver high-quality products efficiently and effectively. Challenges include the high capital investment required to acquire and maintain CNC machines, as well as the ongoing need to train and retain skilled machinists. The success of machine shops in Eugene, Oregon, is inextricably linked to their ability to invest in and effectively manage their CNC machining capacity, ensuring they can meet the evolving needs of local industries and maintain a competitive edge.

5. Quality Assurance Compliance

Quality assurance compliance is integral to the operation of a machine shop in Eugene, Oregon. Adherence to established quality standards, such as ISO 9001 or AS9100, directly impacts the shop’s ability to secure contracts and maintain a reputable standing within the industry. Non-compliance results in loss of business, increased liability risks, and potential damage to its reputation. Consider a scenario where a machine shop produces components for a medical device manufacturer; stringent quality control measures are necessary to ensure the parts meet precise specifications and are safe for their intended use. Failure to comply with relevant quality standards jeopardizes the medical device’s safety and the manufacturer’s regulatory compliance.

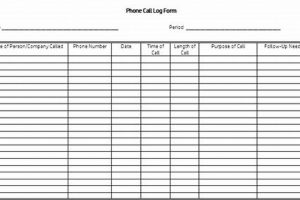

The practical application of quality assurance compliance involves implementing documented procedures for inspection, testing, and documentation. This includes calibrating measuring equipment, maintaining accurate records of inspections, and performing regular internal audits. For example, a machine shop might employ coordinate measuring machines (CMMs) to verify the dimensional accuracy of machined parts, meticulously documenting the results to demonstrate compliance with specified tolerances. Further application lies in rigorous supplier qualification processes, ensuring that raw materials meet defined quality criteria, preventing downstream manufacturing defects.

In conclusion, quality assurance compliance is not merely a bureaucratic requirement but a fundamental aspect of a machine shop’s operational effectiveness and long-term viability. Overcoming the challenges of implementing and maintaining a robust quality management system requires a commitment from leadership, ongoing training for employees, and continuous improvement efforts. Effective quality assurance compliance is essential for building trust with customers, mitigating risks, and sustaining a competitive advantage. This creates a crucial service for manufacturing.

Machine Shop Eugene Oregon

This section addresses common inquiries regarding manufacturing establishments located in the specified geographic area.

Question 1: What types of machining services are commonly offered by machine shops in Eugene, Oregon?

These establishments typically provide CNC milling, CNC turning, welding, fabrication, and prototyping services. The specific range of services varies depending on the size and specialization of the individual shop.

Question 2: What industries do these machine shops generally serve?

Industries served often include aerospace, medical, agricultural, automotive, and general manufacturing. The prevalence of specific industries may fluctuate based on regional economic factors.

Question 3: How does a business determine the most suitable machine shop for a particular project?

Factors to consider include the shop’s experience with the required materials, available equipment, quality control certifications, and capacity to meet project deadlines.

Question 4: What are typical cost factors associated with machining services?

Costs are generally influenced by material type, part complexity, required precision, quantity of parts, and the machine shop’s overhead expenses.

Question 5: Is it possible to obtain prototype parts from these machine shops?

Many machine shops offer prototyping services, enabling clients to validate designs and test functionality before committing to full-scale production.

Question 6: What quality control measures are typically employed by machine shops in the region?

Quality control measures often encompass dimensional inspection using coordinate measuring machines (CMMs), material testing, and adherence to industry standards such as ISO 9001.

Careful consideration of these factors facilitates informed decision-making when selecting a machine shop.

The following section explores the process of requesting quotes from machine shops.

Machine Shop Eugene Oregon

This exploration has highlighted the key aspects of machine shops in the Eugene, Oregon region, emphasizing the importance of precision machining capabilities, material expertise, prototyping services, CNC machining capacity, and quality assurance compliance. Each of these elements contributes significantly to a shop’s ability to meet the diverse needs of local industries and maintain a competitive edge in the manufacturing sector.

The continued success of machine shops in Eugene, Oregon, depends on their commitment to technological advancement, workforce development, and adherence to rigorous quality standards. Businesses requiring precision manufacturing services should carefully evaluate potential partners based on these criteria to ensure project success and long-term value. The economic vitality of the region is inextricably linked to the strength and capabilities of its local machine shops.