The phrase identifies a set of locations within a specific city that are considered superior choices for hosting a high school prom. These locations often possess desirable characteristics such as ample space, appealing aesthetics, suitable amenities (catering, sound systems, lighting), and accessibility for attendees. An example would be a historic ballroom with a dance floor and dedicated event staff, situated conveniently near public transportation within the metropolitan area.

Selecting an appropriate site for a prom significantly impacts the overall experience for students, faculty, and organizers. The venue sets the atmosphere, influences the logistical planning, and contributes to the event’s success. Historically, prom venues have ranged from school gymnasiums to upscale hotels, reflecting evolving trends in student preferences and budgetary considerations.

The subsequent sections will address key factors in evaluating potential locations, examine some examples of establishments commonly chosen for such events, and provide guidance on navigating the selection process.

Venue Selection Guidance

The process of identifying locations suitable for a high school prom requires careful consideration of various factors. The following guidelines are intended to assist in making informed decisions.

Tip 1: Establish a Budget: A clearly defined budget serves as the primary constraint. Venue costs, including rental fees, catering expenses, and potential add-ons, must align with available financial resources.

Tip 2: Determine Attendance Projections: Estimating the number of attendees is crucial for selecting an appropriately sized space. Overcrowding should be avoided, while excessively large spaces may lack ambiance.

Tip 3: Assess Location Accessibility: The venue’s location should be readily accessible to students, faculty, and chaperones. Proximity to public transportation or ample parking facilities are important considerations.

Tip 4: Evaluate Available Amenities: Assess the venue’s existing infrastructure, including sound systems, lighting capabilities, and available staging. Additional costs may be incurred to supplement inadequate amenities.

Tip 5: Review Catering Options: Determine whether the venue provides in-house catering services or allows external vendors. Taste testing and menu selection are essential components of this process.

Tip 6: Consider Aesthetic Appeal: The venue’s overall ambiance and dcor should align with the desired theme or atmosphere of the prom. Architectural details, lighting, and decorative elements contribute to the event’s visual impact.

Tip 7: Verify Contractual Agreements: Thoroughly review all contractual agreements with the venue, paying close attention to cancellation policies, liability clauses, and payment schedules. Legal counsel may be advisable.

By carefully considering these aspects, event planners can effectively narrow down the selection to venues that meet the specific requirements and preferences for a successful prom.

The subsequent section will provide examples of specific establishments often utilized for such events.

1. Capacity

Capacity, referring to the maximum number of individuals a venue can comfortably and safely accommodate, is a primary determinant in selecting from potential candidates. An under-sized venue causes overcrowding, leading to discomfort, safety hazards, and a diminished experience. Conversely, a space significantly exceeding attendance numbers can lack atmosphere and appear sparsely populated. The connection between capacity and achieving a superior prom environment is therefore direct and significant.

For example, a smaller venue like a historic event space might offer exceptional charm and architectural appeal but be unsuitable for a graduating class of 300 students. A larger convention center, while capable of hosting a large group, might require extensive decoration and rearrangement to create an intimate atmosphere, incurring additional costs. Furthermore, the availability of restrooms, adequate egress points, and staff support are all directly affected by the venue’s capacity relative to the event’s attendance.

Therefore, accurate attendance projections are crucial. These projections must be realistic and account for potential variations in turnout. The ideal option for such events offers a capacity slightly exceeding the expected attendance, allowing for comfortable movement and unforeseen attendees while retaining a sense of cohesive atmosphere. Identifying venues that can strike this balance is a fundamental step in securing a suitable setting that contributes positively to the overall event.

2. Accessibility

Accessibility, in the context of venue selection, represents a critical factor affecting event attendance and overall participant satisfaction. Its relevance to location choice is multifaceted, encompassing physical, transportation, and economic dimensions. Locations deemed superior prioritize comprehensive accessibility to ensure inclusivity and convenience.

- Physical Access

Physical access considerations include features such as ramps, elevators, and accessible restrooms, ensuring individuals with mobility impairments can fully participate in the event. A location lacking these features may exclude a portion of the student body, contravening principles of inclusivity. Example: A historic building with limited modifications for accessibility may pose challenges compared to a modern facility designed with universal access standards.

- Transportation Access

Transportation access encompasses proximity to public transit, availability of parking, and ease of navigation to the venue. Locations readily accessible by public transportation benefit students without personal vehicles. Ample parking facilities cater to attendees who drive. A location distant from public transit or lacking sufficient parking may deter attendance. Example: A venue located directly on a MAX line offers superior transportation access compared to a site requiring circuitous routes and transfers.

- Economic Access

Economic accessibility relates to the cost associated with attending the event, including transportation expenses, ticket prices, and any required attire. Venues located in areas with high transportation costs or necessitating expensive formal wear may disproportionately affect students from lower socioeconomic backgrounds. Example: A venue in a central location with readily available and affordable public transportation options improves economic accessibility.

- Informational Access

Informational access considers the clarity and availability of information regarding the venue, event details, and accessibility features. A venue with a poorly designed website or lacking clear signage may create confusion and impede access for attendees. Example: A venue that provides detailed accessibility information on its website, including photos and descriptions of accessible features, facilitates informed decision-making.

In summation, prioritizing venue accessibility enhances event inclusivity and participation rates. When seeking superior sites, a comprehensive assessment of physical, transportation, economic, and informational facets is imperative. A location’s designation as an appropriate choice is directly tied to its capacity to accommodate diverse needs and ensure equitable access for all attendees.

3. Aesthetics

Aesthetics play a crucial role in determining the suitability of locations. The visual appeal and overall ambiance of a venue directly influence the perceived quality and memorability of the event. A site’s aesthetic qualities contribute significantly to the creation of a desired atmosphere.

- Architectural Style and Design

A venue’s architectural style sets the tone and creates a visual backdrop for the event. Historic buildings with ornate details, modern spaces with sleek lines, or outdoor settings with natural landscapes each offer a distinct ambiance. Example: A grand ballroom with high ceilings, chandeliers, and intricate moldings provides a sense of elegance and formality, while a repurposed industrial space with exposed brick and minimalist design offers a contemporary and unconventional atmosphere.

- Interior Decor and Furnishings

The interior decor, including color schemes, lighting, furniture, and decorative elements, contributes to the overall aesthetic experience. Cohesive design and attention to detail enhance the venue’s visual appeal. Example: Soft lighting, elegant drapery, and comfortable seating create a romantic and inviting atmosphere. In contrast, bright colors, modern art, and minimalist furnishings offer a more vibrant and contemporary aesthetic.

- Landscaping and Exterior Features

For venues with outdoor spaces, landscaping and exterior features significantly impact the aesthetic. Well-maintained gardens, scenic views, and attractive outdoor lighting enhance the overall experience. Example: A venue with a lush garden, fountains, and illuminated pathways provides a romantic and picturesque setting. Alternatively, a rooftop terrace with panoramic city views offers a sophisticated and modern aesthetic.

- Adaptability to Themes and Decorations

The ability of a venue to adapt to different themes and decorations is an important aesthetic consideration. A neutral space with flexible design elements allows for customization and personalization. Example: A blank canvas space with minimal permanent fixtures provides ample opportunity for transforming the venue to suit a specific theme, such as a Hollywood gala or a masquerade ball.

In summary, the aesthetic qualities of a potential site significantly impact the overall experience. Venues exhibiting architectural appeal, cohesive interior decor, attractive landscaping, and adaptability to themes contribute positively to the event, supporting its designation as a possible choice. Neglecting the aesthetic component can result in a less memorable and less satisfying experience, diminishing the venue’s suitability, irrespective of other positive attributes.

4. Amenities

The availability and quality of amenities are critical determinants in assessing the suitability of a location for a high school prom. Venues deemed superior offer a comprehensive range of services and facilities that enhance the event experience and contribute to its success. Deficiencies in essential amenities can detract significantly from participant satisfaction and logistical efficiency.

- Catering Services

Catering services encompass food and beverage provisions, including menu options, service style (buffet, plated dinner), and dietary accommodations. High-quality catering services offer diverse and appealing menu choices, accommodating dietary restrictions and preferences while maintaining appropriate presentation and service standards. Example: A venue with in-house catering providing customizable menus, accommodating vegetarian, vegan, and gluten-free options, exemplifies superior service. Inadequate catering can lead to dissatisfaction and negatively impact the event’s overall perception.

- Audio-Visual Equipment

Audio-visual (AV) equipment includes sound systems, lighting, projectors, and screens. The presence of professional-grade AV equipment is essential for music playback, speeches, presentations, and creating the desired ambiance. Example: A venue equipped with a high-quality sound system, intelligent lighting, and a large projection screen enhances the entertainment value of the event. Insufficient or malfunctioning AV equipment can disrupt the flow of the event and diminish its impact.

- Dance Floor and Staging

A dedicated dance floor provides a designated space for attendees to engage in dancing, a central activity at most proms. Staging facilities are essential for speeches, performances, and presentations. The size and quality of the dance floor and staging area should be appropriate for the expected attendance and planned activities. Example: A venue with a spacious, well-maintained dance floor and a raised stage with professional lighting enhances the event’s functionality and aesthetic appeal. An inadequate dance floor or staging area can limit participation and impact the event’s dynamics.

- Restrooms and Facilities Maintenance

Adequate restroom facilities are essential for attendee comfort and hygiene. Regularly maintained restrooms, including accessibility features, contribute to a positive overall experience. The venue’s commitment to cleanliness and maintenance reflects its attention to detail and concern for attendee well-being. Example: A venue with clean, well-stocked restrooms and a dedicated maintenance staff demonstrates a commitment to providing a comfortable and hygienic environment. Insufficient or poorly maintained restroom facilities can negatively impact attendee satisfaction and reflect poorly on the event.

In conclusion, the presence and quality of amenities such as catering services, AV equipment, dance floor and staging, and restroom facilities are critical factors in differentiating among potential sites. Venues offering comprehensive and well-maintained amenities contribute significantly to a positive attendee experience, thereby reinforcing their suitability as a location for such an event.

5. Cost

The cost associated with securing a location significantly influences its categorization within the spectrum of locations available. Financial constraints invariably shape the selection process, often necessitating a trade-off between desired amenities and budgetary realities. For instance, a grand ballroom with comprehensive catering and AV services may exceed the allocated financial resources, forcing event organizers to consider more economical, albeit less elaborate, options. The interplay between available funds and desired features is central to identifying a suitable location. The expense of a location is determined by rental fees, catering charges, service costs, and potential incidentals. Each of these components contributes to the total expenditure and must be carefully considered. A lower-priced venue may seem advantageous initially, but additional expenses for external catering, equipment rentals, or decor can quickly escalate the overall cost, potentially surpassing the expense of a more inclusive, albeit initially higher-priced, alternative. Consequently, a thorough and transparent cost analysis is essential to avoid budget overruns and ensure fiscal responsibility.

The ramifications of cost extends beyond the immediate financial impact. An excessively expensive location may necessitate increased ticket prices, potentially limiting participation from students with financial constraints. Conversely, prioritizing a low-cost venue at the expense of essential amenities or a desirable atmosphere may diminish the overall experience and student satisfaction. Balancing cost considerations with the need to provide an enjoyable and inclusive experience requires careful deliberation and creative problem-solving. Fundraising efforts, sponsorship opportunities, and negotiation with venue management are strategies commonly employed to mitigate financial pressures and enhance the overall value proposition. Successful management requires understanding budget limitations and the impact they may have.

In summary, cost is a primary determinant in the designation of what are locations. The financial resources available, alongside careful consideration of both direct and indirect expenses, shapes the selection process. A balanced approach, accounting for both budgetary limitations and the need to provide a high-quality experience, is essential. Thorough financial analysis and creative strategies for mitigating costs are crucial for successful execution of the event while maintaining financial solvency.

6. Availability

In the context of identifying top-tier locations, availability represents a fundamental and often limiting factor. Even the most desirable site is rendered unsuitable if it cannot be secured for the event date. Competition for prime dates, particularly during peak prom season, significantly impacts the selection of establishments, regardless of their aesthetic appeal, amenities, or cost-effectiveness. Therefore, assessing and confirming availability is among the initial and most critical steps in the venue selection process.

- Date Specificity and Booking Windows

Proms are typically scheduled for specific dates during the spring months. This concentrated demand creates intense competition for prime locations, especially those renowned for their ambiance and suitability for large gatherings. Booking windows, the period within which reservations are accepted, vary among locations, often extending a year or more in advance. Failure to initiate the booking process sufficiently early can result in the unavailability of preferred sites. For instance, a sought-after ballroom may already be reserved for a corporate event or wedding if inquiries are made too late in the planning cycle.

- Contractual Obligations and Hold Policies

Venues typically employ contractual agreements to secure reservations, outlining financial obligations, cancellation policies, and event parameters. Hold policies, which allow prospective clients to provisionally reserve a date while finalizing their decision, can impact availability. A venue with a liberal hold policy may temporarily block availability, preventing other potential clients from securing the date, even if the initial client ultimately cancels. Understanding a venue’s hold policy is crucial for assessing the true likelihood of securing a reservation.

- Venue Capacity and Double Booking Risks

Venues with multiple event spaces may attempt to maximize revenue by booking multiple events simultaneously. While not inherently problematic, this practice can strain resources, impacting service quality and creating logistical challenges. Evaluating a venue’s capacity to manage multiple events concurrently, and ensuring contractual protections against double-booking, is essential. For instance, a hotel ballroom hosting both a prom and a corporate conference may experience service delays or noise conflicts, detracting from the overall experience.

- Staffing and Resource Constraints

Even if a venue appears available on a given date, underlying staffing and resource constraints can limit its suitability. Insufficient catering staff, security personnel, or technical support can compromise the quality of service, negating the perceived advantages of the location. Assessing a venue’s capacity to adequately staff the event and provide necessary resources is critical. A venue that can accommodate the number of attendees within the location’s capacity, can cause a variety of issues.

In conclusion, the availability of potential locations, while seemingly straightforward, is a complex factor influenced by date specificity, booking windows, contractual obligations, venue capacity, and resource constraints. Thorough investigation and proactive planning are essential to secure a suitable site, mitigating the risk of settling for a less desirable option due to unavailability. Effective date management and diligent communication with venue representatives are fundamental to this process.

Frequently Asked Questions About Prom Venue Selection

The following questions address common inquiries and concerns regarding the identification and selection of sites suitable for hosting a high school prom within the Portland, Oregon metropolitan area.

Question 1: What is the optimal timeframe for commencing the venue search process?

The recommended timeframe is at least twelve months prior to the intended event date. Popular locations frequently experience high demand, necessitating early inquiry and reservation.

Question 2: What is the typical cost range associated with securing a location?

Cost varies significantly based on venue size, amenities, and date. A comprehensive budget should be established prior to contacting potential sites to ensure financial feasibility. Expect a range from several thousand to tens of thousands of dollars.

Question 3: How does one evaluate the accessibility of a potential site for attendees with disabilities?

A physical site visit is recommended to assess compliance with accessibility standards, including ramps, elevators, and accessible restroom facilities. Consult venue management regarding available accommodations.

Question 4: What contractual provisions should be carefully scrutinized prior to signing an agreement?

Cancellation policies, liability clauses, payment schedules, and clauses pertaining to force majeure events warrant thorough review. Legal counsel may be advisable.

Question 5: What measures should be taken to ensure the safety and security of attendees?

Security personnel, emergency plans, and clearly defined protocols for addressing potential incidents are essential. Coordinate with venue management to establish appropriate safety measures.

Question 6: What recourse is available in the event that a venue fails to fulfill its contractual obligations?

The contractual agreement should outline procedures for addressing breaches of contract. Legal action may be pursued to seek damages or specific performance.

Effective venue selection requires diligent research, careful evaluation, and proactive planning. A well-chosen location contributes significantly to the success of the event.

The subsequent section will present a concise summary of the key factors discussed.

Best Prom Venues Portland Oregon

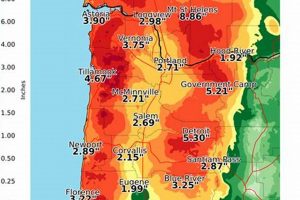

The preceding analysis has delineated the key considerations involved in the identification of best prom venues portland oregon. Factors such as capacity, accessibility, aesthetics, amenities, cost, and availability have been examined, emphasizing their respective influences on the suitability of locations for hosting high school proms. A thorough understanding of these elements is essential for informed decision-making.

Ultimately, the selection of a location requires a balanced assessment of these various criteria, prioritizing those that align most closely with the specific needs and preferences of the student body and event organizers. Diligence in research and planning, coupled with proactive communication with venue representatives, will increase the likelihood of securing a site that contributes meaningfully to a memorable and successful event.

![Portland Riots Today: Unrest in Oregon [LIVE] Living in Oregon: Moving Tips, Cost of Living & Best Cities Portland Riots Today: Unrest in Oregon [LIVE] | Living in Oregon: Moving Tips, Cost of Living & Best Cities](https://blogfororegon.com/wp-content/uploads/2026/01/th-415-300x200.jpg)